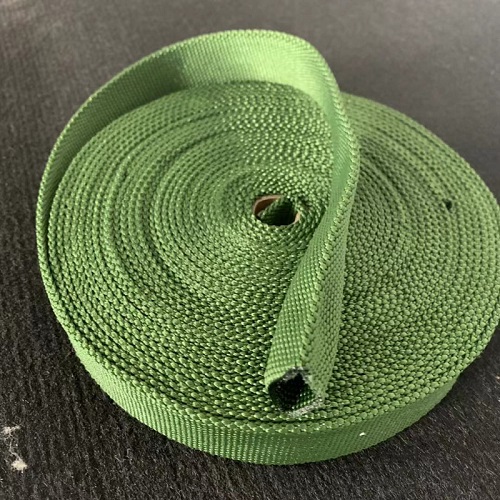

If the ribbon factory wants to produce Selvedge webbing The product has a better production process. To quickly meet the customer's needs, it needs a series of products and production control processes. Next, Huanwei Ribbon mainly explains the ribbon quality control process, and how to correctly test the ribbon products in a series.

The purpose of the process is to clearly define the process operation procedure, so as to ensure that the quality in the process of edging webbing can be reasonably and effectively controlled, and reduce the production of defective products.

1、 Inspect according to the customer's requirements: for example, 336, 217, 115, 314, 108, 114, 384, 206, 419, 122 adhesive paper and hose, and no pins can be tied.

2、 Width detection: width tolerance of 1 "and above shall not exceed ± 0.25 points; The tolerance of width of 25MM and above shall not exceed ± 0.5MM; For widths of 1 "and less than 25MM, the standard tolerance shall not exceed ± 0.25MM.

Note: The flat mouth and herringbone edging must be of sufficient size, but not more than 0.25 points.

3、 Singeing, labeling

1. The quality inspector shall inspect the packaging label to be consistent with the actual goods (specification, color, quantity), and seal it for warehousing.

2. Singeing must be clean, but not scorched.

4、 Control method of tape rolling process:

1. The surface of the tape must be smooth and flat (except for special cases), and it cannot be involved in defective products. Relevant personnel shall be held accountable depending on the seriousness of the case.

Short code: ± 0.5/100Y

Knot: ≤ 3/100Y, ≤ 2/50Y

2. The edging webbing must have the mark of the tape coiler.

5、 Color difference test: there is no yin and yang color on the surface of the tape by naked eye, and the color and texture (the needle edge must be of one color) of the rolled tape needle edge and cloth edge cannot be exchanged.

6、 Thickness inspection: the tolerance shall not exceed ± 0.1MM

7、 Needle skipping: no needle skipping is allowed through naked eye observation.

Contamination: The surface shall be free of oil stain, stain and dust through visual observation.

Hair: through naked eye observation, there shall be no serious hair balls or filaments on both surfaces and sides that may affect the surface of the edging ribbon.