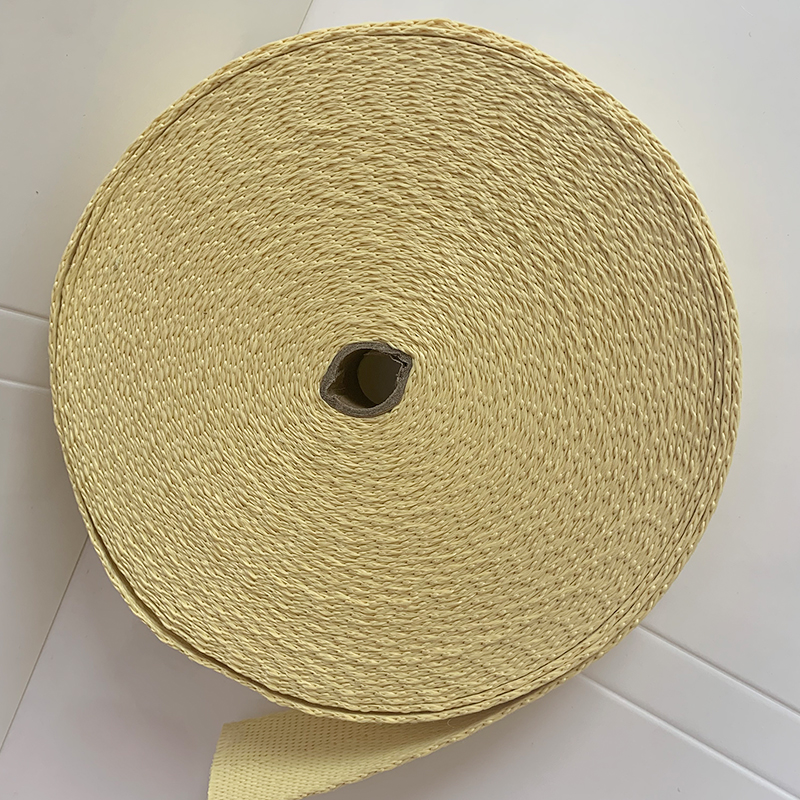

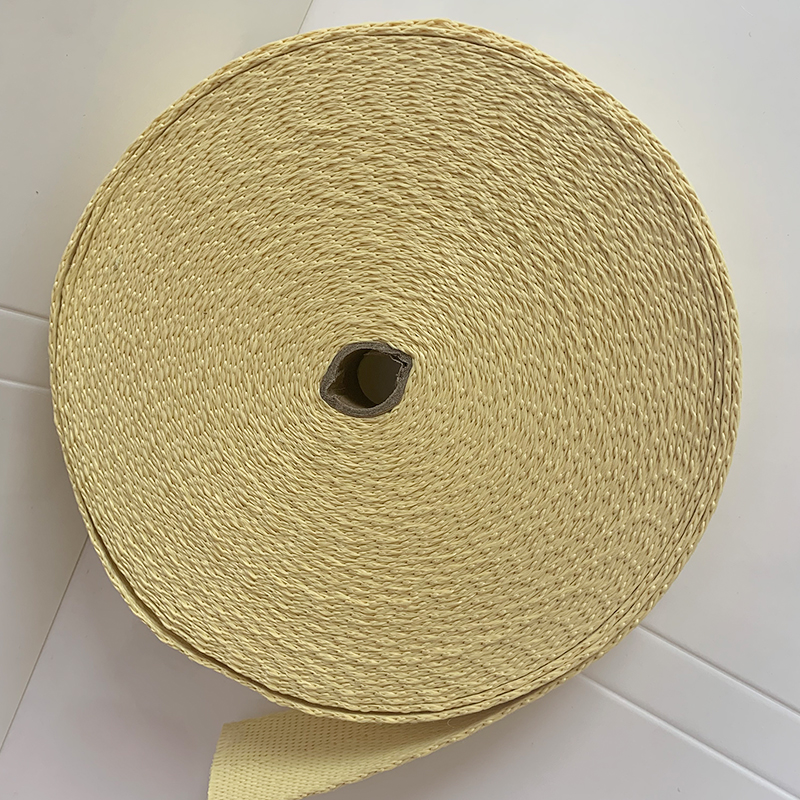

Nylon sheet composite flat belt (also known as high strength flat belt) uses modified polyamide sheet as the bearing layer, the working surface is covered with a friction layer of chrome tanned leather or elastic colloid, and the non working surface is bonded with a rubber cloth or special fabric layer. The tensile strength of nylon sheet is up to 400 MPa, and it has high elastic modulus. After the constant elongation treatment, the composite flat belt has high comprehensive mechanical properties. The covering layer on the working surface can not only enhance the transverse tear resistance of the belt body, but also increase the adhesion to the pulley surface. According to the different covering materials, the friction coefficient with the pulley surface can reach 0.4~0.7, so the nylon sheet composite flat belt has a high bearing capacity. In recent years, the performance of nylon sheet base has been continuously improved, and the product performance has been further improved, and can not be affected by temperature. In addition, flat belts with polyester fabric and aramid fabric as the bearing layer also appeared. Due to the improved manufacturing process, the transmission performance of flat belts, such as strength, belt flexibility and vibration absorption, transmission stability and life, has been greatly improved, showing a good prospect for use.