1 Scope

This standard specifies the product classification, technical requirements, test methods, inspection rules and requirements for marking, packaging, transportation and storage of special industrial nylon filament.

This standard is applicable to the identification of the quality of round section, bright and natural multifilament and monofilament of special industrial nylon 6 and 66.

2 Reference standards

The following standards contain provisions that, through reference in this standard, constitute provisions of this standard. When the standard is published, the versions shown are valid. All standards will be revised. All parties using this standard should explore the possibility of using new versions of the following standards.

GB | 2828-87 | Sampling procedures and tables for lot by lot inspection by attributes |

GB/T | 6502—86 | Sampling method for synthetic filament and textured yarn |

GB/T | 6503—86 | Test method for moisture regain of synthetic filament and textured yarn |

GB/T | 6505-86 | Test method for boiling water shrinkage of synthetic filament and textured yarn |

GB/T | 14343-93 | Test method for linear density of synthetic filament and textured yarn |

GB/T | 14344-93 | Test method for breaking strength and elongation of synthetic filament and textured yarn |

GB/T | 14345-93 | Test method for twist of synthetic filament yarn |

FZ/T | 50003—91 | Test method for dyeing uniformity of nylon filament and textured yarn |

3 Product classification

The special industrial nylon filament can be divided into the following four categories:

3.1 Twisting, press washing and setting of multifilament

3.2 Untwisted, pressure washed and unshaped multifilament

3.3 Twisted and shaped multifilament

3.4 Monofilament

4 Technical Requirements

The product grade of special industrial nylon filament is one grade for special products.

4.1 Twisting, press washing and setting of multifilament

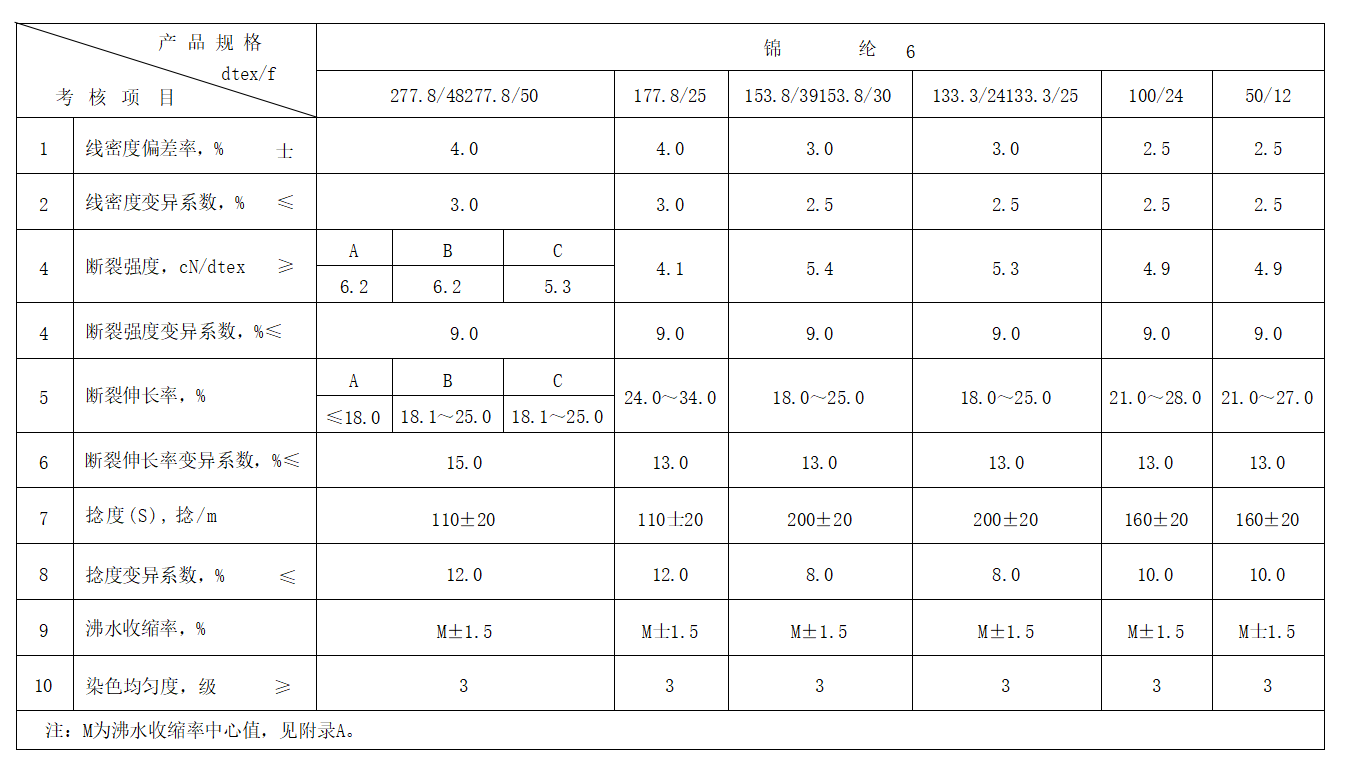

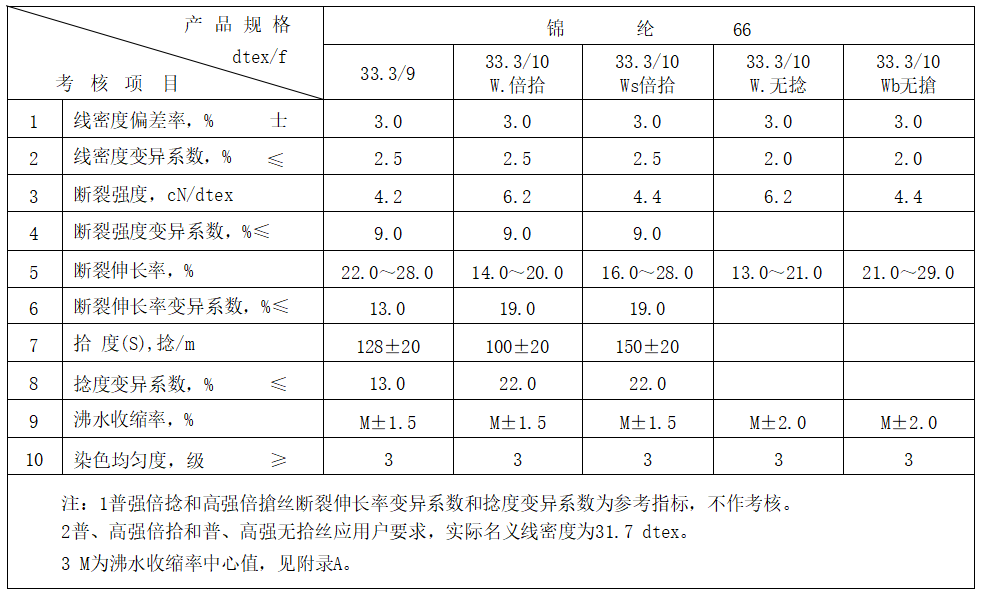

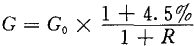

4.1.1 See Table 1 for physical and mechanical performance indexes.

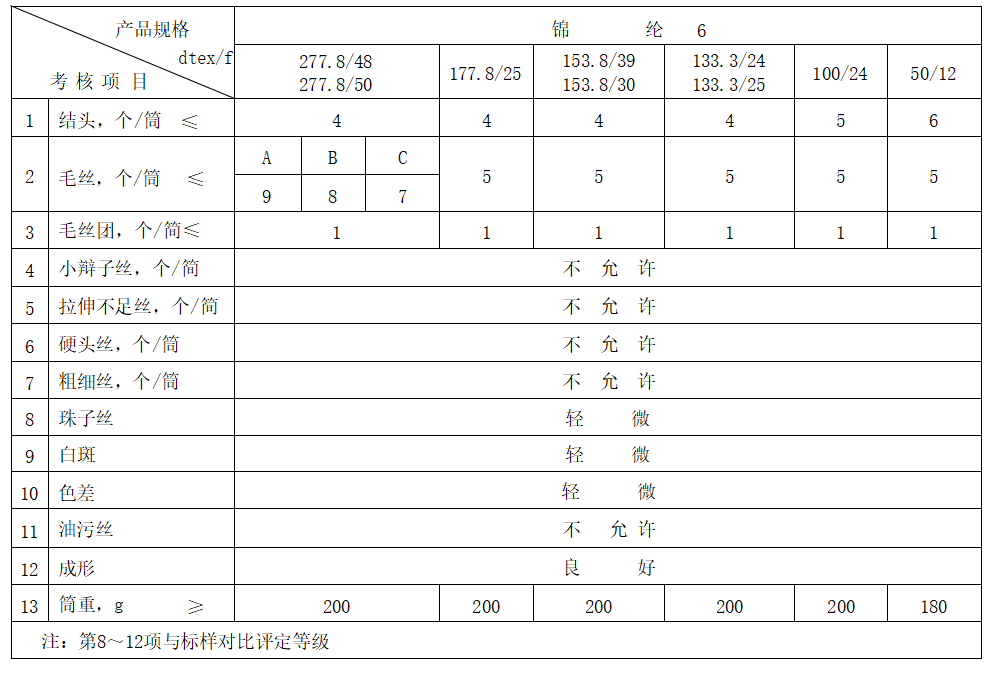

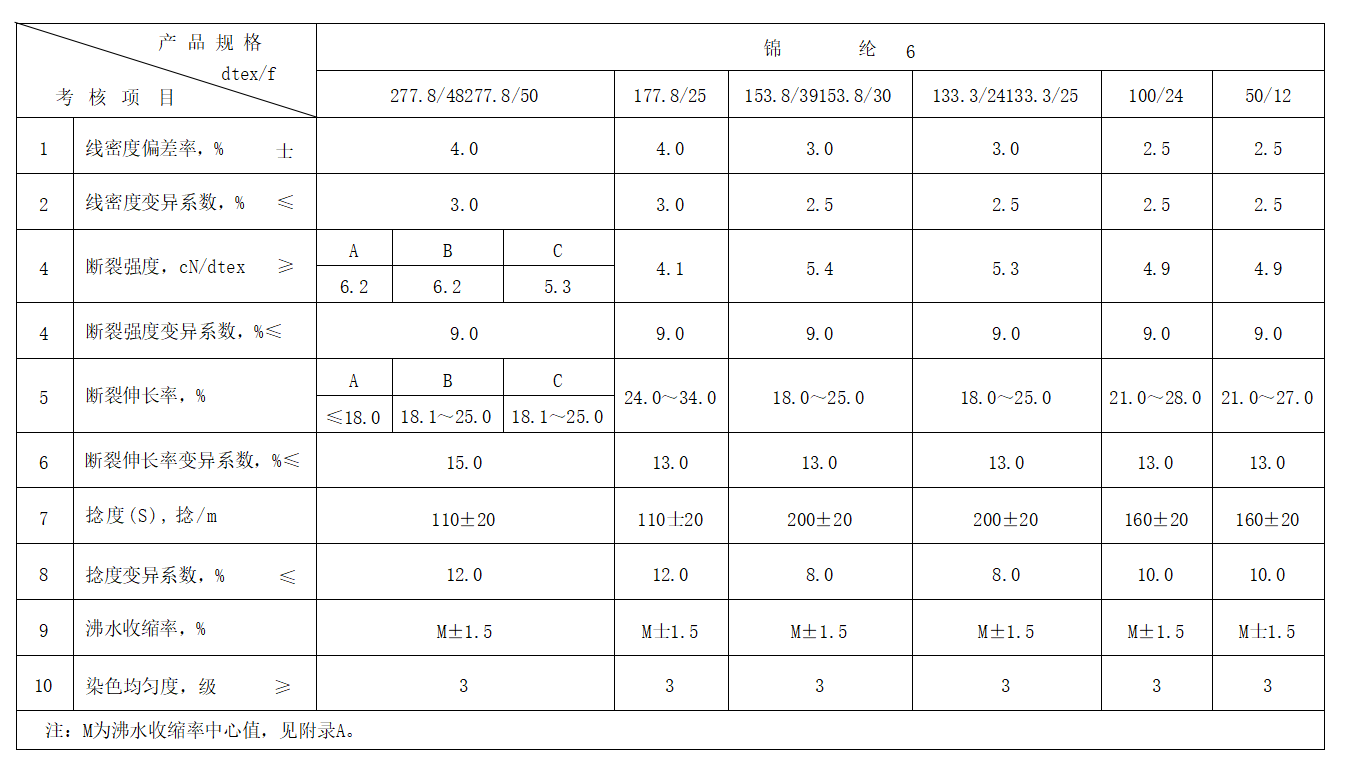

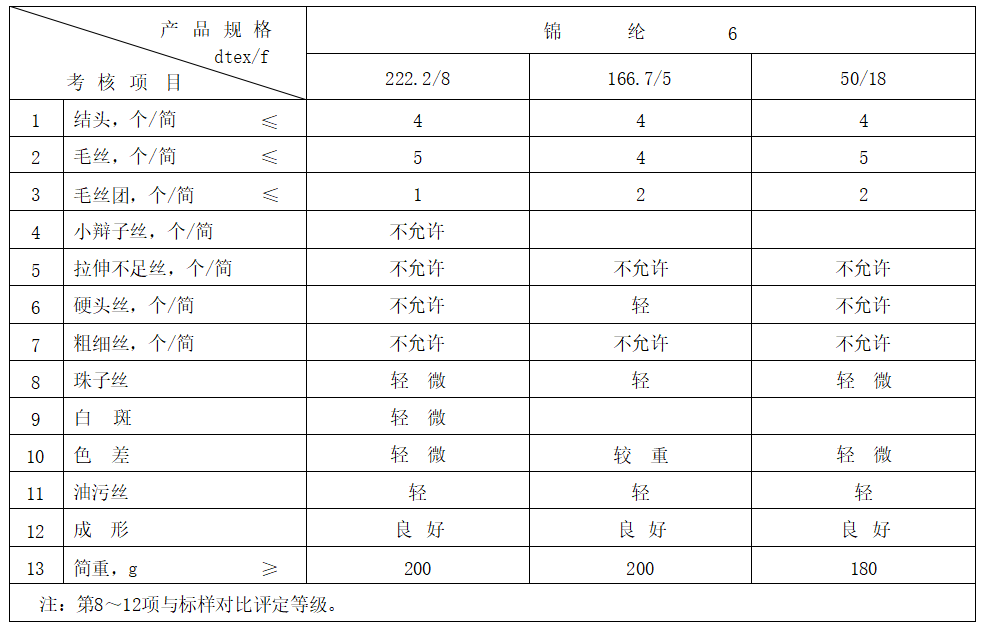

4.1.2 See Table 2 for appearance quality indicators.

4.2 Untwisted, pressure washed and unshaped multifilament

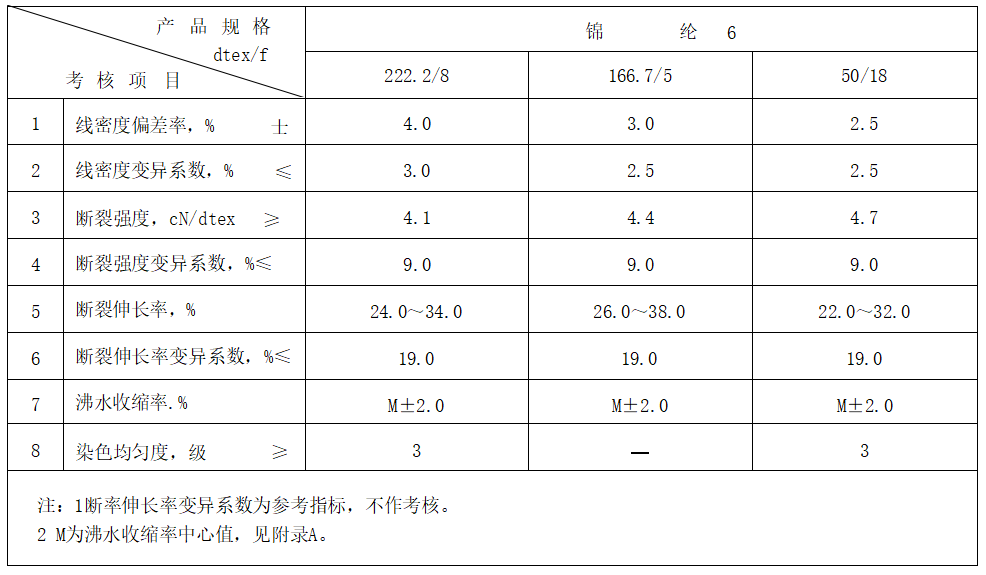

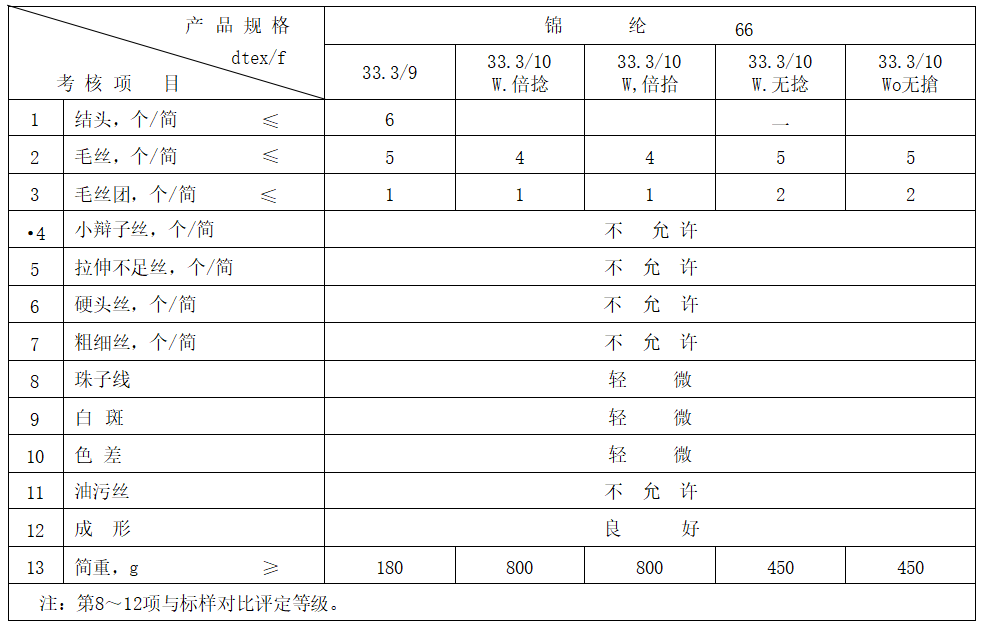

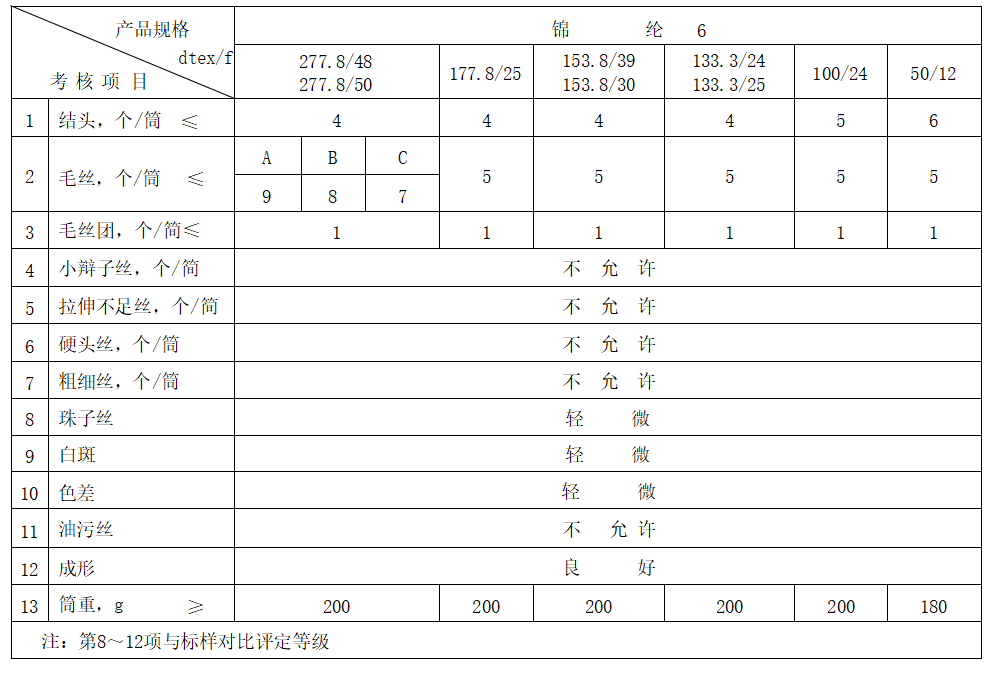

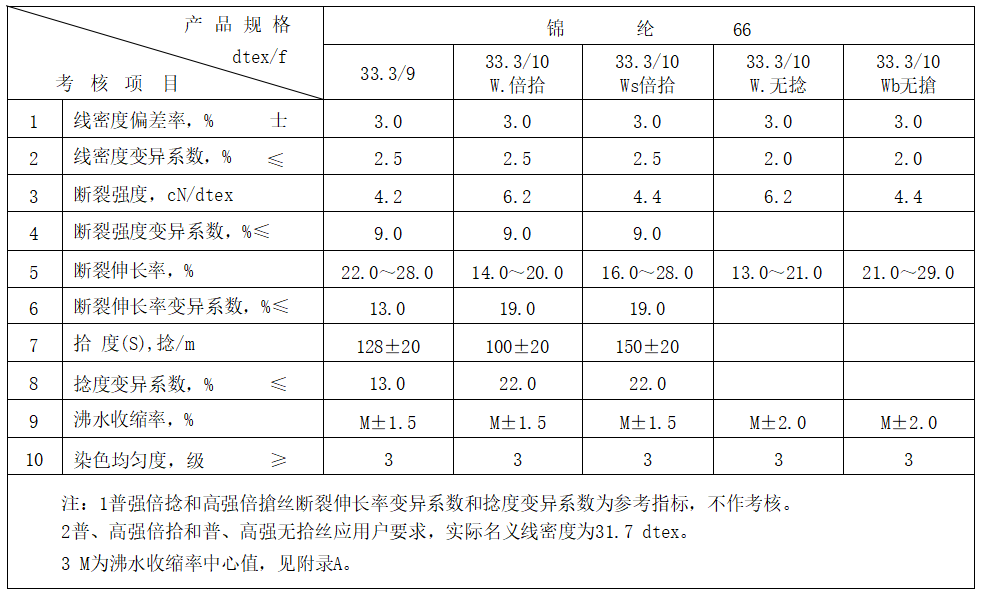

4.2.1 See Table 3 for physical and mechanical performance indexes.

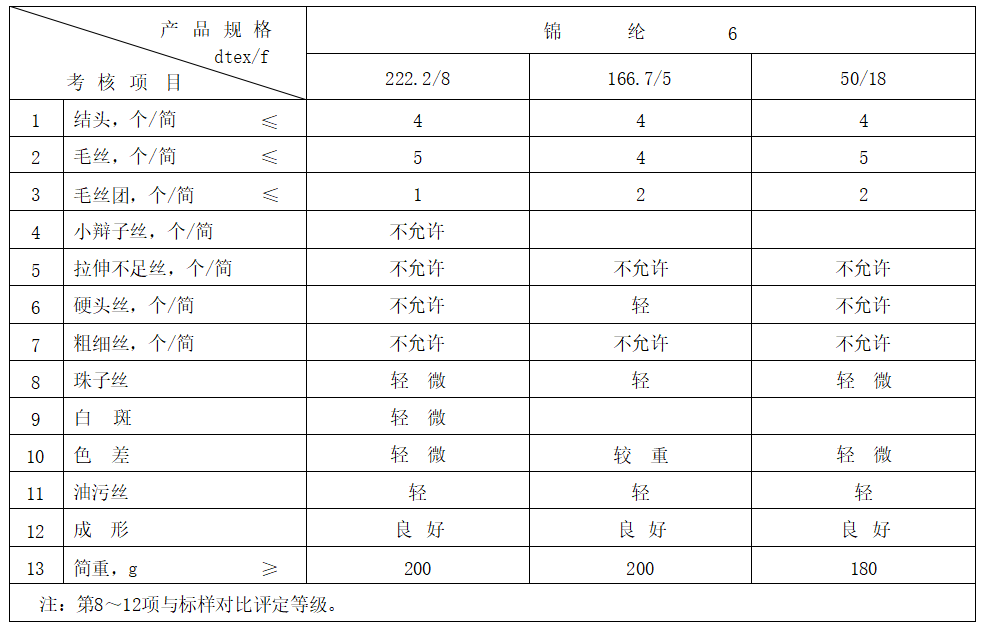

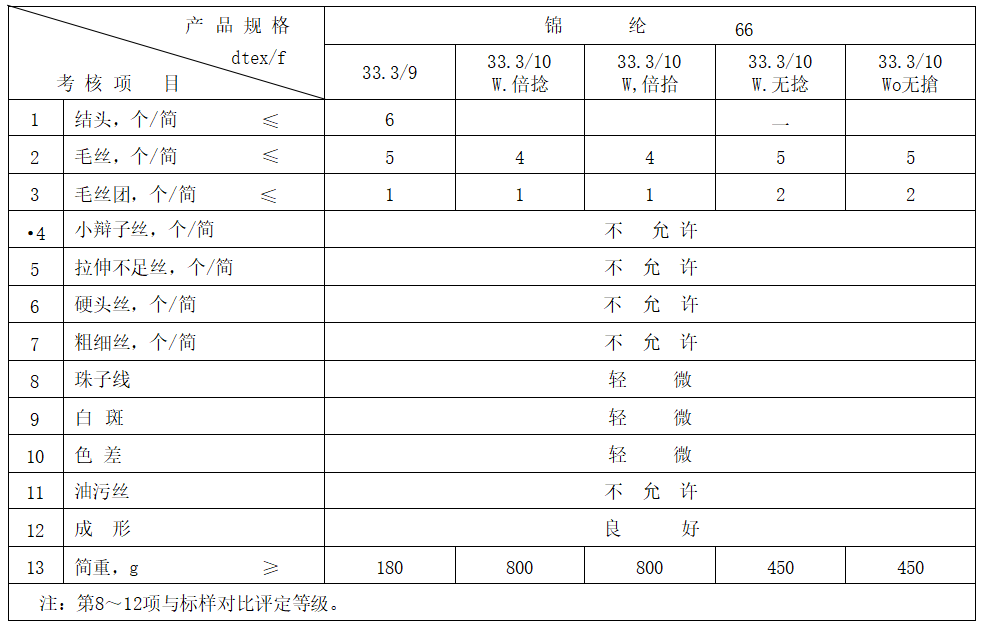

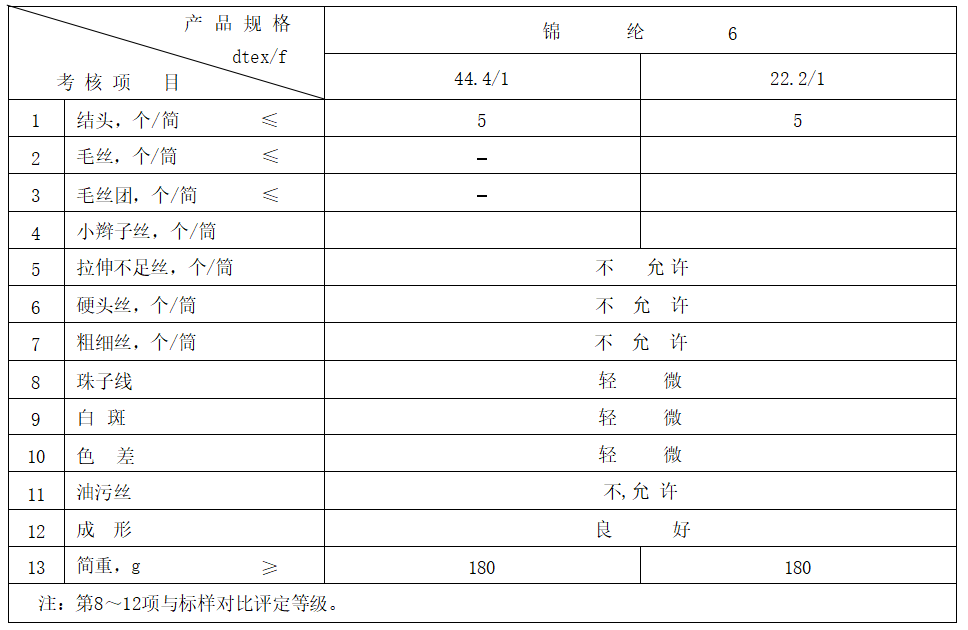

4.2.2 See Table 4 for appearance quality indicators.

4.3 Twisting and setting compound

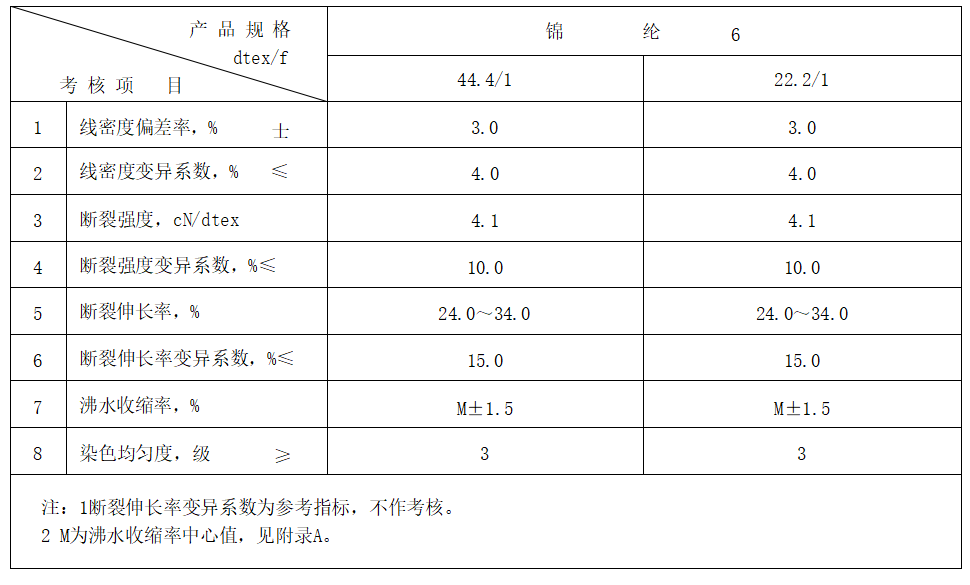

4.3.1 See Table 5 for physical and mechanical performance indexes.

4.3.2 See Table 6 for appearance quality indicators.

4.4. Monofilament

Table 1 Physical and Mechanical Performance Indexes of Twisted, Pressed and Washed and Stereotyped Composite Filament

Table 2 Appearance Indexes of Twisting, Press Washing and Setting Compound Yarn

Table 3 Physical and mechanical properties of untwisted, pressure washed and unshaped multifilament

Table 4 Appearance indexes of untwisted, pressure washed and unshaped multifilament

Table 5 Physical and Mechanical Performance Indexes of Twisted and Set Compound Filament

Table 6 Appearance index of twisted and shaped multifilament

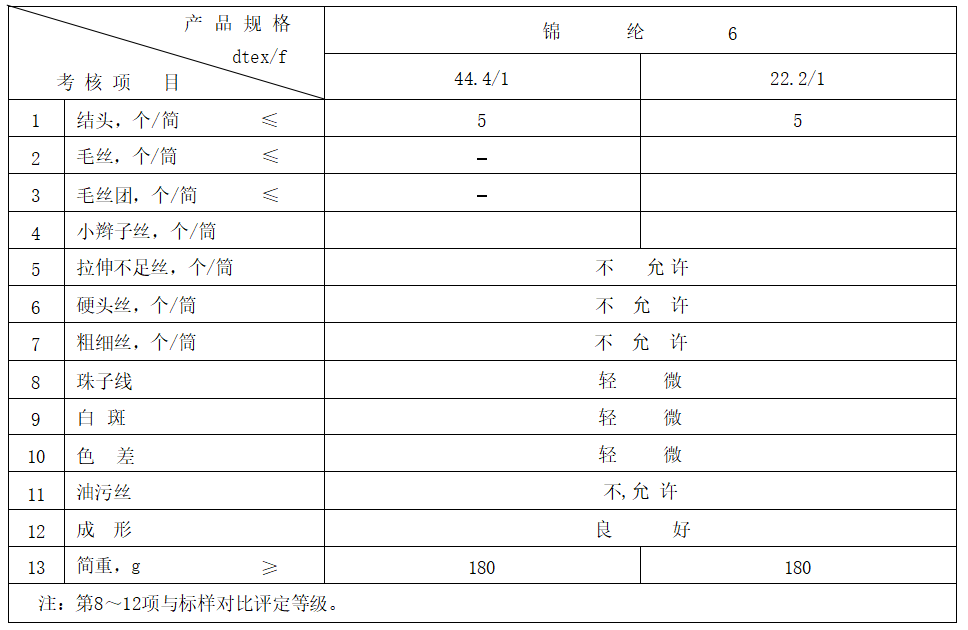

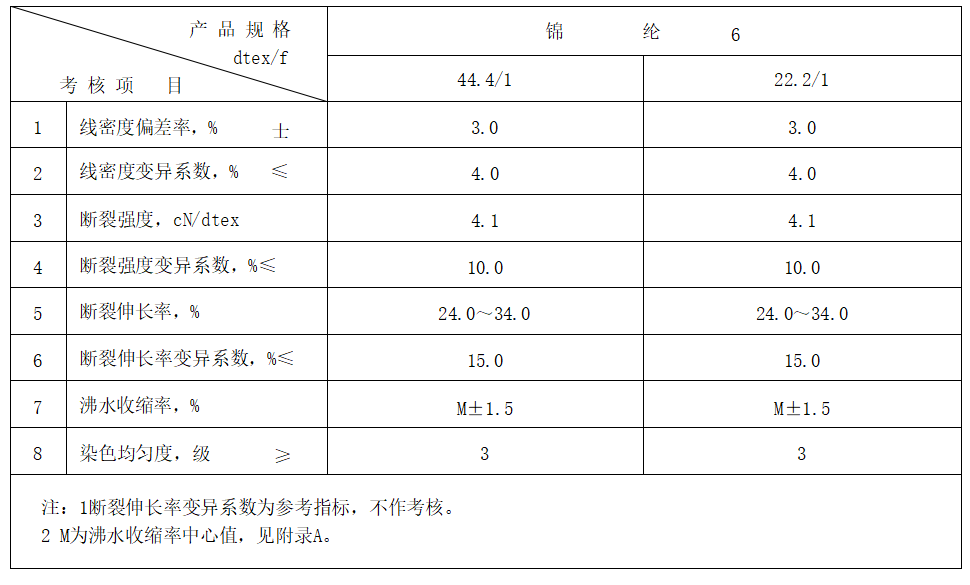

Table 7 Physical and Mechanical Performance Indexes of Monofilament

Table 8 Appearance index of monofilament

4.4.1 See Table 7 for physical and mechanical performance indexes.

4.4.2 See Table 8 for appearance quality indicators.

5 Test method

5.1 Linear density

The linear density test shall be carried out according to the provisions of GB/T 14343, and the calculation of linear density shall be in accordance with Formula (3).

5.2 Breaking strength and elongation at break

The breaking strength and elongation test shall be carried out according to the provisions of GB/T 14344, and the constant speed traction single yarn tensile tester (CRT) shall be used as the tensile tester.

5.3 Twist

The twist test shall be conducted according to GB/T 14345. 5.4 Boiling water shrinkage

Boiling water shrinkage test shall be conducted according to GB/T 6505.

5.5 Dyeing uniformity

Dyeing uniformity test shall be conducted according to FZ/T 50003.

5.6 Moisture regain

The moisture regain test shall be conducted according to the provisions of GB/T 6503.

5.7 Number of decimal places

See Table 1, Table 3, Table 5 and Table 7 for the decimal places of test results.

6 Inspection rules

6.1 Delivery inspection

6.1.1 Inspection items

During the delivery inspection, the physical and mechanical properties shall be inspected according to the items specified in Table 1, 3, 5 and 7 of this standard; The appearance quality shall be inspected according to the items specified in Table 2, 4, 6 and 8.

6.1.2 Batch regulations

6.1.2.1 Each batch of products must be raw materials, chemical materials, processes, equipment, varieties, specifications and appearance grades. If the number of products produced continuously reaches more than 720 packages, it is a production batch.

6.1.2.2 In case of abnormal production, the product shall be divided into different batches, and the products in different batches shall be tested with two samples, and the grade of the batch of products shall be evaluated with the difference of the test results.

6.1.3 Sampling regulations

The laboratory samples for physical and mechanical property test shall be sampled from a batch of products with the same appearance grade according to GB/T 6502. If the production volume increases, the sample can be taken at 2% of the total number of products in the batch.

6.1.4 Appearance quality inspection method

6.1.4.1 Equipment and tools

Grading table and various defect standard samples.

6.1.4.2 Lighting conditions

Two milky white 40W lamps, with a lampshade depth of 18~20 cm, coated with white enamel paint or matte white paint. There is no scattered light around. The illumination at the inspection bobbin is about 4001x.

6.1.4.3 Inspection method

Appearance inspection shall be carried out one by one. The grader shall hold the big and small ends of the bobbin with both hands beside the grading table, identify one place to start rotating when the bobbin to be inspected is about 40 cm away from the lamp tube, visually inspect the defects on the two end faces and cylindrical surface of the bobbin according to Appendix B, and evaluate the grade of the bobbin according to Table 2, 4, 6 and 8 of this standard.

6.1.5 Evaluation of inspection results

The physical and mechanical properties are evaluated by batch, and the grade of the lower item in the technical requirements is determined as the grade of this batch of products.

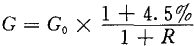

6.1.6 Rated weight

Where: G -- public weight, kg;

G ₀ - net weight, kg;

R -- measured moisture regain,%.

6.2 Re inspection rules

6.2.1 Re inspection shall be conducted according to the original production batch number.

6.2.2 The laboratory samples for physical and mechanical property test shall be sampled for re inspection according to the provisions of GB/T 6502.

6.2.3 During the re inspection, the appearance quality inspection shall be sampled according to the provisions of General Inspection Level II in GB 2828, and the batch of products shall be judged as qualified or unqualified according to the provisions of the AQL value of 4.0 in the sampling plan for one-time normal inspection in GB 2828. When it is judged as unqualified, this batch of products shall not be allowed to leave the factory when they are in the manufacturer, and shall be settled by the user through negotiation.

6.2.4 If a batch of products has any objection to the quality within three months after arriving at the user's factory, it can be submitted to a full-time inspection agency for re inspection. If it exceeds three months, it is not allowed to apply for re inspection. However, if the quality or storage and transportation quality of special industrial nylon yarn affects the quality of post processed products and causes serious losses, the supplier and the demander shall analyze the causes, clarify the responsibilities and negotiate for solutions.

6.2.5 Other provisions for re inspection are the same as those for delivery inspection.

7 Marking, packaging, transportation and storage

7.1 Marks

The carton shipping mark shall be marked with the manufacturer's name, product name, specification, grade, batch number, gross weight, net weight, number of packages, production date, trademark, standard number, damp proof, handle with care and other marks.

The mark of batch number is: ×××××

The first number represents the process

Section Two figures indicate the month of production

The third number represents the batch number

7.2 Packaging

7.2.1 Each silk drum of special industrial nylon filament must be wrapped with moisture-proof paper or covered with polyethylene plastic bags, and packed according to different varieties, specifications, batch numbers, grades, and production dates. The silk slips shall not be damaged or contaminated during packaging. The slips shall be upright.

7.2.2 The packing box and its folder shall be solid, dry and clean, and the packing paper or plastic bag shall not be stained with color.

7.2.3 Product quality inspection sheet shall be attached to each box of products. Contents include: factory name, variety, specification, grade, batch number, various inspection data and date, etc., and stamped with the special seal of the quality inspection department.

7.2.4 Each drum shall be labeled with the manufacturer's name, variety, specification (linear density, number, twist, twist direction), production batch number and job number.

7.3 Transportation

The outer package shall not be damaged during transportation, and the carton shall not be inverted or damped.

7.4 Storage

Special industrial nylon filaments shall be stacked in batches and stored in dry, clean and ventilated warehouses.

The center value of boiling water shrinkage rate agreed by each manufacturer and user factory is shown in the following table, which shall not be changed at will.

| varieties | Factory name | Boiling water shrinkage center value (%) |

6—277.8 dtex 6-277.8 dtex (untwisted) | Chongqing Synthetic Fiber Factory Beijing Synthetic Fiber Test Plant Shanghai No.9 Chemical Fiber Factory Shanghai No.9 Chemical Fiber Factory | 4.5(B) 4.2(C) 7.0 five thirteen |

6-222.2 dtex 6-177.8 dtex | Beijing Synthetic Fiber Test Plant | five five |

6-153.8 dtex 6-166.7 dtex (untwisted) | Chongqing Synthetic Fiber Factory Beijing Synthetic Fiber Test Plant Shanghai No.9 Chemical Fiber Factory Shanghai No.9 Chemical Fiber Factory | two point five six point five three point three thirteen point five |

| 6-133.3.dtex | Chongqing Synthetic Fiber Factory Shanghai No.9 Chemical Fiber Factory | two point two 3.5 |

| 6—100 dtex | Shanghai No.9 Chemical Fiber Factory Chongqing Synthetic Fiber Factory | three point five 2.2 |

6—50 dtex 6-50 dtex (no grab) | Chongqing Synthetic Fiber Factory Shanghai No.9 Chemical Fiber Factory Shanghai No.9 Chemical Fiber Factory | two point two three point five 11.5 |

66-33.3 dtex W 66-33.3 dtex (double twist) Wb 66-33.3 dtex (untwisted) W 66-33.3 dtex (untwisted) W | Shanghai No.9 Chemical Fiber Factory | nine nine point five 10.0 ten |

6-44.4 dtex 6—22.2 dtex | Tianjin Synthetic Fiber Factory | five point five 6.0 |

Classification, term interpretation and specific provisions of appearance defects

| defects classification | Terminology | Specific provisions | remarks |

| one | Knot | Nodule connecting two wire heads | 1 Knot is required to stay on the same slope of the bobbin 2 The tail wire of knot shall be less than 5 mm |

|

| two | Wool | The broken head of a single fiber on the surface of a simplet in a multifilament or a loose looped wire in a ring shape | 1. Loosely looped yarn with several monofilaments in the same shape at the same point on the package surface without double twisting, calculated as one wool yarn 2. There are three or less monofilaments with the same shape at the same point on the surface of the cylinder, It is calculated as one filament, and more than three filaments are calculated as one wool ball |

|

| three | Wool ball | Broken wire head or continuous loose loop wire protruding from the surface of the cylinder | 1 Due to the influence of the wool ball, the wool that appears continuously on both sides of the wool ball of the same root fiber will not be examined 2. If there is continuous loose ring protruding from the same fiber on the surface of the cylinder, it shall be calculated as one wool ball |

|

| four | Small Fenzi Silk | In the recovered silk, the twist of short segments is too tight, in the form of small braids | One small bobbin shaped tow on the surface of the package, making one small bobbin |

|

| five | Understretched wire | The short and medium segments of the fiber are not stretched enough, the yarn is thicker, and the fluorescent white silk can be obviously stretched |

|

|

| six | Bead silk | Extremely small punctate grains in the filaments on the surface of a simple particle | The length of point grain is less than 2 mm | Slight refers to 6 ≤ 5 pieces of nylon

Nylon 66 ≤ 30 pieces |

| seven | Hard headed silk | The small dot crystal or monofilament appearing in the filament strip on the surface of the Jane, and the thick hard head wire protruding from the surface of the Jane after fracture | The length of point grain is greater than or equal to 2 mm | 66-33.3 dtex hard wire, 5 pieces allowed |

| eight | Leukoplakia | Silk with white spots, white frost and white stripes on the surface of bamboo slips |

|

|

| nine | chromatic aberration | There is difference in the surface color of the cylinder, or the whiteness of the whole cylinder is different from that of the standard cylinder | 1. The degree of difference shall be evaluated according to GB 250-94. Grey sample calipers for color change shall be used 2 The whiteness standard sample shall be determined by each factory. If the whiteness is selected as the standard sample, the difference of level 4 color difference is allowed when grading; If the end point of whiteness is selected as the standard sample, it is not allowed to be lower than the standard whiteness when grading 3 When comparing the whiteness of the standard sample package and the measured package, they should be placed on the same plane and compared repeatedly | Slight refers to grade 4 of sample card |

| ten | Greasy silk | Yellow and black oil stains or rust stains on the bamboo slips | Any oil stain and rust stain greater than 0.5 mm |

|

Classification, term interpretation and specific provisions of appearance defects (continued)

| defects classification | Terminology | Definite | remarks |

| eleven | become type no good | The package is too hard, too soft, uneven on three sides, the threads on the inclined plane cross into a spider net, and the package position is improper |

1 roll is too soft: As the package is too loose during the forming process, there is obvious depression on the flat or inclined surface of the package when pressed down with fingers, and the width of soft silk on the upper or lower inclined surface of the package is greater than or equal to 2 mm 2 Uneven: The three sides of the package are uneven, and the concave convex depth is more than 1.5 mm 3 Spider wire: ① The width of any cross filament on the package is more than 3 mm, forming a circle ② If the height of the winding bar on the package is less than 5mm, and there are more than 6 pieces at the upper end, the lower end is strict, and more than 1 piece at the lower end is also considered as poor forming ③ If the height of the upper thread of the nail is more than 5mm and the upper end is more than 3, the lower end is not allowed 4 Improper packaging position ① The length of the outer plane of the package is less than two-thirds of the length of the outer plane of the normal filament ② The bobbin winding position is less than or equal to 5 mm from both ends of the bobbin

| 1. Measurement method for unevenness of three surfaces on the cylinder: The ruler shall be parallel to the three planes respectively, and the deepest concave convex of the three planes shall be measured 2. Height measurement method for the radian of spider wire and sliver: It shall be measured from the bottom of the line that the wire strip should take on the slope to the top of the arc |

| twelve | Bobbin Too small | The package weight is lower than the lower limit specified in the standard |

|

|