Range

This standard specifies the technical requirements, appearance defect inspection, test methods, inspection rules, marks and packaging of special industrial canvas. This standard is applicable to the identification of special industrial canvas.

Reference standards

The following standards contain provisions that, through reference in this standard, constitute provisions of this standard. When the standard is published, the versions shown are valid. All standards will be revised. All parties using this standard should explore the possibility of using new versions of the following standards.

GB 250-94 Grey scale for assessing discoloration

GB 3920-83 Test Method for Color Fastness to Rubbing of Textiles

F265001-1995 Test Method for Physical and Mechanical Properties of Special Industrial Fabrics

FZ 65004-1995 Test Method for Chemical Properties of Special Industrial Textiles

FZ 65006-1995 Marking and Packaging of Special Industrial Textiles

FZ 66102-1995 Special industrial cotton cloth (I)

FZ 65008-1995 Inspection rules for special industrial textiles

technical requirement

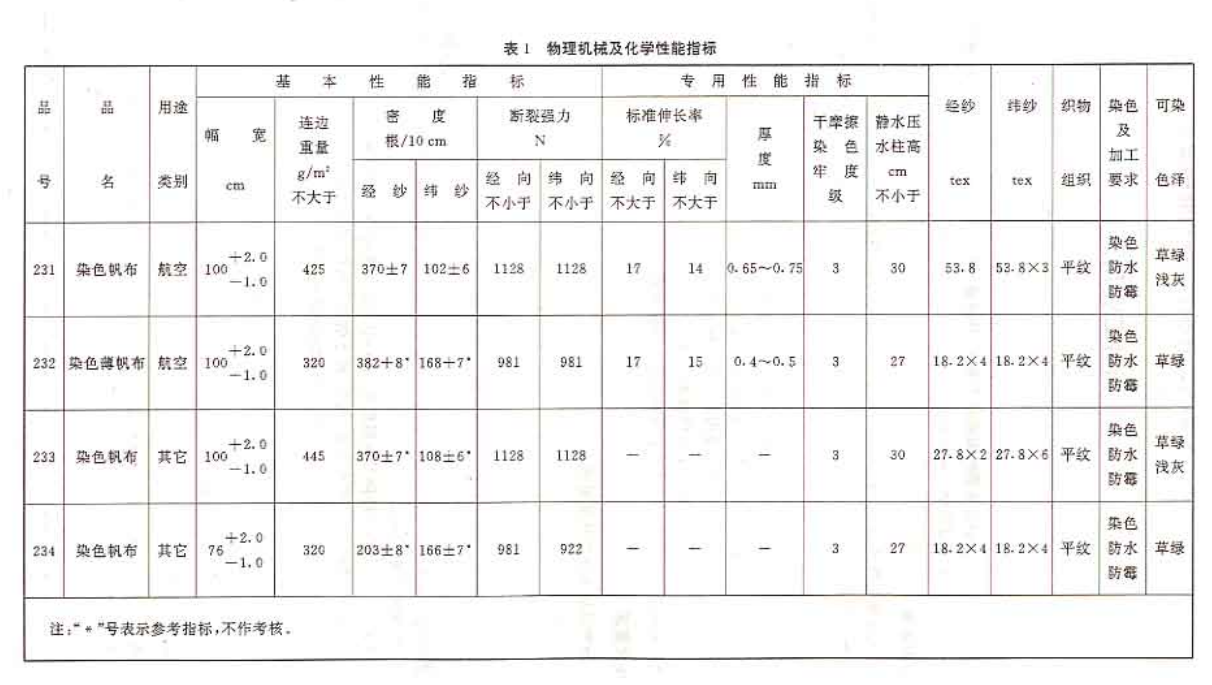

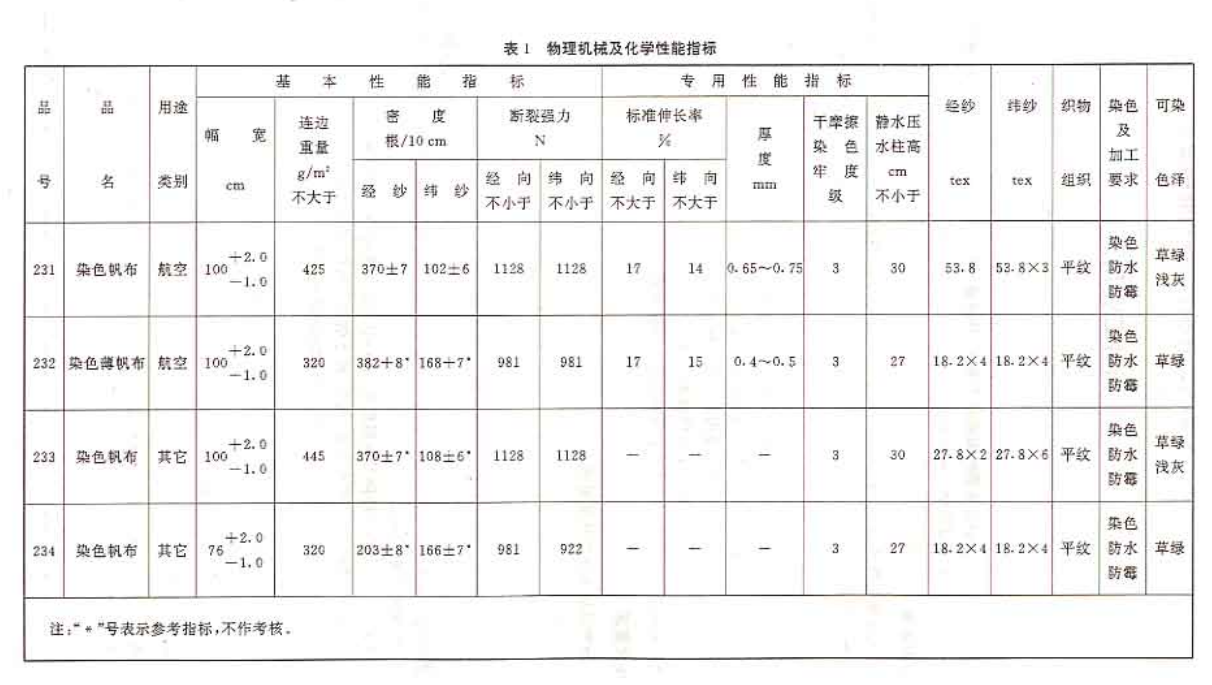

3.1 See Table 1 for physical, mechanical and chemical properties.

3.2 Appearance defects

3.2.1 See Table 2 for the scope of appearance defects.

3.2.2 See Table 3 for the agreed length and allowable number of defects.

3.2.3 The number of defects allowed shall be controlled within the specified piece length. The range of defects is shown in Table 2. For such defects, the manufacturer shall mark the white line on one side of the cloth during inspection. When it is not at the starting point of the range of defects, no defects are allowed. The defects beyond the scope of defects shall be cut or pseudo cut. In case of false slitting, the unfading line shall be marked on one side of the cloth, and the manufacturer shall deduct the length of the false slitting at the time of delivery.

3.2.4 Description of appearance defect evaluation

According to 3.3 in FZ.66102-1995 Special Industrial Cotton Cloth (I), and make the following supplements.

3.2.4.1 Shuttle rolling, unsticking, poor trimming, knots, more than twice the thickness of coarse weft, sundries weaving in, and unsticking are not allowed.

3.2.4.2 White core showing cloth surface desquamation is not allowed, but moving single continuous white wire is allowed.

3.2.4.3 The defect length shall be measured by large length in warp or weft direction.

3.2.4.4 The unlisted defects shall be evaluated as similar defects according to their impact on use.

3.2.5 Description of appearance defects

According to 3.4 in FZ 66102-1995 Special Industrial Cotton Cloth (I).

Appearance defect inspection

The inspection of appearance defects shall be carried out according to the relevant provisions of GB/T 411 cotton printed and dyed fabrics, and according to the use requirements of special industrial canvas, it is stipulated that the appearance must be inspected on both sides one by one.

Table 2 Scope of Defect Detection

S/N | Defect name | Scope of symptoms | remarks |

one | Menstruation | Broken single piece length 3~10 cm |

|

two | Broken weft | The length of single fracture is 2-5cm |

|

three | Fine weft | The fineness shall not be less than 1/3 of the original yarn diameter, and the length along the warp direction shall not exceed Icm |

|

four | Wei Shao | The weft yarn is twisted and weaved into the cloth, causing loops to float on the cloth surface, no more than 2 per meter |

|

five | Sparse weft | It is obvious that the sparse weft is 1 piece lower than the lower tolerance of weft density within 1 em along the longitudinal direction |

|

six

| Skip yarn | 1. Single skip yarn is less than 0.5 cm, and 4~6 pieces are within 50 cm of warp length

2. Skip 0.5 cm or more for defect detection |

|

seven | Oiled yarn | The length of oiled yarn and spun yarn along the warp or weft is 15-30 cm |

|

eight

| Broken edge | Not more than 0.5 cm deep into the cloth, each 12 cm long | 2 broken edges on the side without spots |

nine | Take off quickly | 0.5~1cm deep into the cloth, 3~5 in one piece |

|

ten | Deep and shallow edges | 2-3 cm deep into the cloth, and the length along the edge shall not exceed 100 cm |

|

eleven

| Oil stain

Dirty class, Banyan | The degree of oil shift, stain, stain and shift collapse shall be in accordance with GB 250-94

The gray sample card used for color change assessment is lower than grade 3, and each length is 2-5 em | Subject to positive assessment |

twelve

| Border flower | Evident degree shall be evaluated for discoloration according to GB 250-94

The gray sample card is not lower than level 2, 2~- 10 cm away from the edge |

|

thirteen

| Bar transverse

Rosette | The degree of color and luster shall be evaluated according to GB 250-94

Compared with the dyed streaks lower than grade 3, the width of the damaged band is 0.2~1cm, and the length is 20~50cm |

|

fourteen

| chromatic aberration | Color difference of front, rear, left and right shall be evaluated according to GB 250-94

The gray sample card is qualified if it is not lower than grade 3 |

|

fifteen

| Latitudinal declination | It is qualified if the weft line is deflected in a straight line or deflected in an arc by 231% or less,

Other machine cloth is qualified if it does not exceed 2.0% |

|

Table 3 Allowable number of defects for agreed piece length

Item No | Product Name | purpose class other | Specified piece length and allowable tolerance m | Minimum segment length and false open

Minimum distance between shears m | Shortage of specified length

Allowed quantity in% | Number of standard shifts allowed | Allowable number of false shearing |

two hundred and thirty-one | Dyed canvas | aviation | 40-5 | three | five | five | two |

two hundred and thirty-two | Dyed canvas | aviation | 40-5 | three | five | five | two |

two hundred and thirty-three | Dyed facing cloth | other | 40-5 | three | five | ten | three |

two hundred and thirty-four | Dyed canvas | other | 40-5 | three | five | seven | three |

Note; The manufacturer shall deliver the single piece to the user. |

test method

The color fastness test shall be carried out according to the provisions of GB 3920.

The physical and mechanical performance test shall be carried out according to the provisions of FZ 65001.

The chemical property test shall be carried out according to FZ 65004.

Inspection rules

The inspection rules shall be in accordance with FZ 65008.

Mark and package

Marking and packaging shall be in accordance with FZ 65006.