1 Scope

This standard specifies the technical requirements, appearance defect inspection, test methods, inspection rules, marks and packaging of special industrial cotton cloth (I). This standard is applicable to the identification of special industrial cotton cloth (I).

2 Reference standards

The following standards contain provisions that, through reference in this standard, constitute provisions of this standard. When the standard is published, the versions shown are valid. All standards will be revised. All parties using this standard should explore the possibility of using new versions of the following standards.

GB 250 - 94 Grey scale for assessment of discoloration

GB 3920 - 83 Test Method for Color Fastness to Rubbing of Textiles

GB 3921-83 Test Method for Color Fastness to Washing of Textiles

GB 5714 - 85 Test Method for Color Fastness to Sea Water

FZ 65001 - 1995 Test Method for Physical and Mechanical Properties of Special Industrial Fabrics

FZ 65004 - 1995 Test Method for Chemical Properties of Special Industrial Textiles

FZ 65006 - 1995 Marking and Packaging of Special Industrial Textiles

FZ 65008 - 1995 Inspection Rules for Special Industrial Textiles

3 Technical Requirements

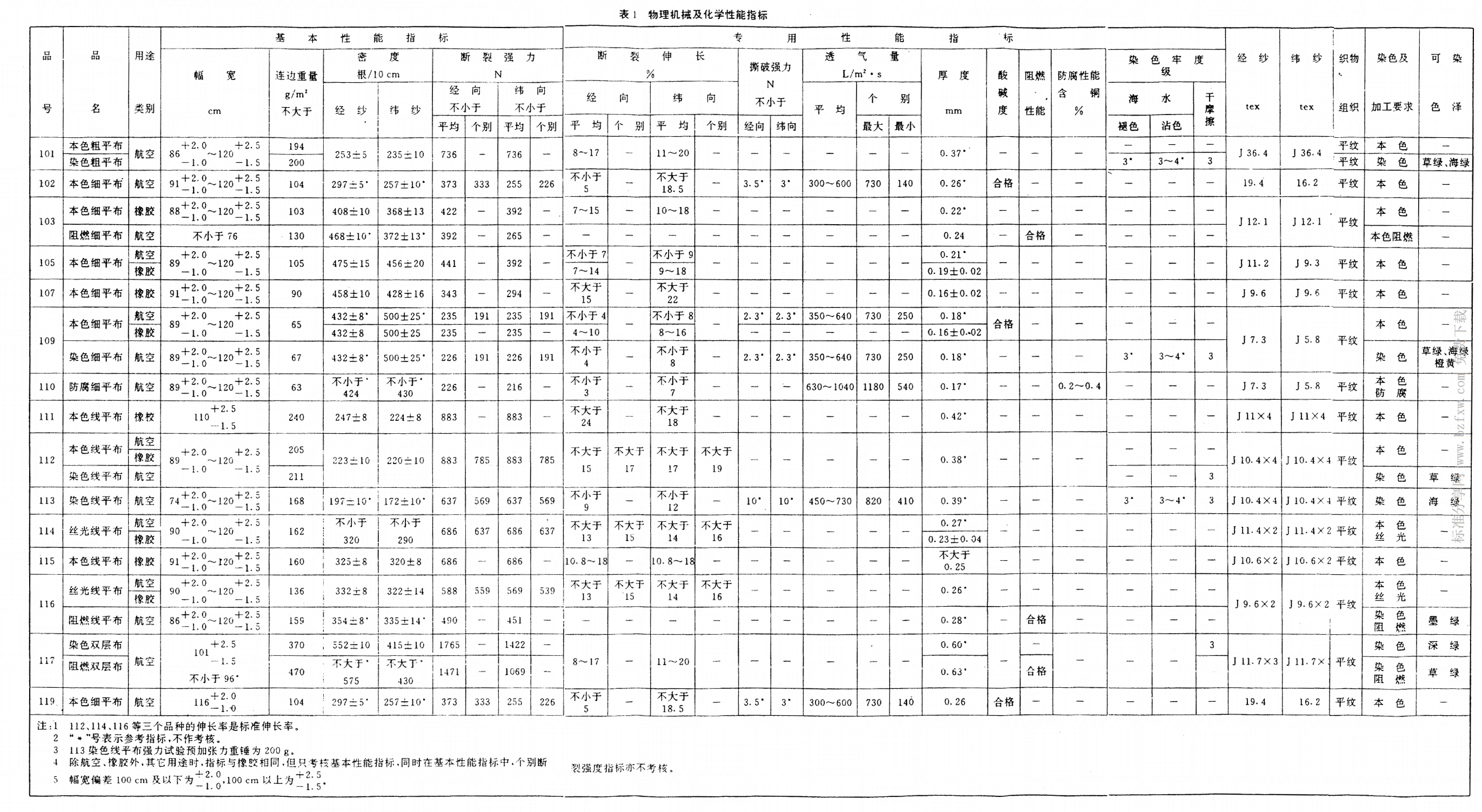

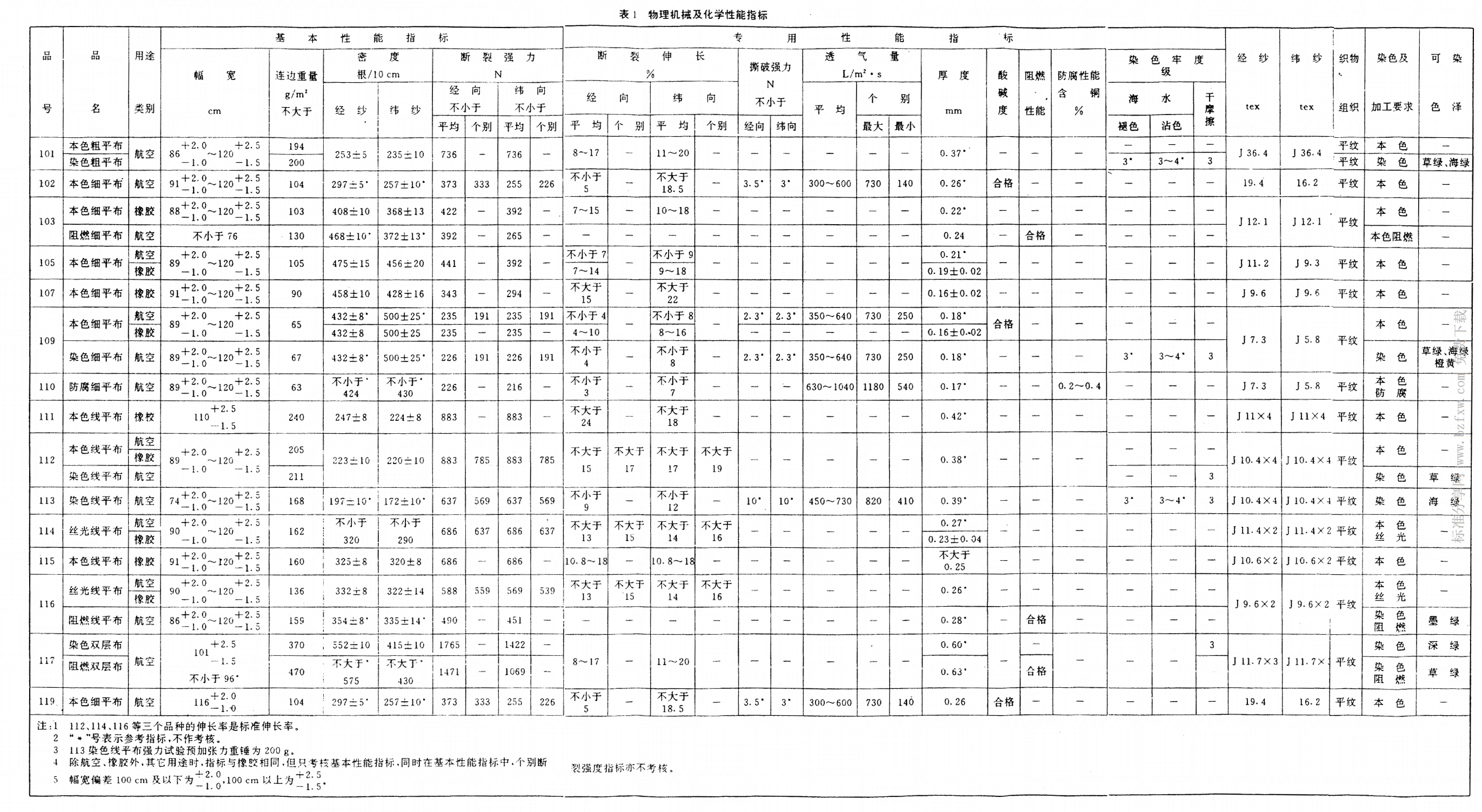

3.1 See Table 1 for physical, mechanical and chemical performance indexes.

3.2 Appearance defects

3.2.1 The range of marked defects (hereinafter referred to as defects) of appearance defects is shown in Table 2.

3.2.2 See Table 3 for the agreed length and allowable number of defects.

3.2.3 Within the specified piece length, the number of defects allowed shall be mastered, and the range of defects is shown in Table 3. During inspection of such defects, the manufacturer shall sew white lines on one side of the cloth for marking. When not reaching the starting point of the range of defects, no defects shall be made. It is generally not allowed. The defects beyond the range of defects shall be cut or false cut. In case of false slitting, the unfading line shall be marked on one side of the cloth, and the manufacturer shall deduct the length of the false slitting at the time of delivery.

3.3 Description of appearance defect evaluation

3.3.1 No more than one defect per meter.

3.3.2 The defect length shall be measured by the length in warp or weft direction.

3.3.3 All kinds of fabric defects, if appearing on both sides within 0.2m along the warp direction at the same time, shall be evaluated as serious ones.

3.3.4 The following kinds of defects are not allowed, and the defects shall be cut or false cut. Such as shuttle rolling, thinning, untied and unstitched, sundries weaving in, weft shedding, poor repair, mechanical damage, thick and thin sections, holes, double warp reed roads, and open edges. When the product is used for rubber cloth, all the above defects shall be removed.

3.3.5 The unlisted defects shall be evaluated as similar defects according to the degree of impact on use.

3.3.6 If the length of cloth is more or less than the length specified in this article, the allowable number of defects shall be converted proportionally.

3.4 Description of appearance defects

3.4.1 Warp breaking - including warp breaking and weft breaking. "Two broken yarns in total" refers to breaking two warp yarns or two weft yarns or breaking one warp yarn or one weft yarn.

3.4.2 Mechanical damage - edge support defect, yarn body fuzzing or broken yarn caused by pricking roller.

3.4.3 Poor repair refers to fuzzing or creping caused by defect correction.

Table 2 Scope of Defect Detection

S/N | Defect name | Scope of defect detection | remarks |

Aviation and others | rubber |

one | Menstruation | 1. Single yarn is broken, and the yarn fabric is 10-20 cm long. Half yarn fabric and yarn fabric are 2-5 cm long 2. Two pieces in total are broken, and half thread fabric and thread fabric with a length of 0.5~2 cm are not allowed | 1. Single yarn is broken, and the yarn fabric is 10~30cm long. Half yarn fabric and yarn fabric are 2~5cm long 2. It is not allowed to cut two yarns in total, half thread fabric and thread fabric with length of 0.5~2 cm |

|

two | A secret road | The obvious secret road exceeds the upper latitude tolerance per centimeter along the warp direction: 1. Three with density below 300/10cm 2. The density is 300 pieces/10 cm and above 4 pieces | The obvious secret road, Exceeding the upper latitude density tolerance per centimeter along the warp direction: 1. Three with density below 300/10cm 2. The density is 300 pieces/10 cm and above 4 pieces |

|

three | Sparse weft | The obviously visible sparse weft exceeds the lower tolerance of weft density per centimeter along the warp direction: 1. 2-3 pieces with density below 300 pieces/10cm 2. 3~4 pieces with density of 300 pieces/10cm and above | not allow |

|

four | Coarse meridian Tight warp Slung sutra Meridional contraction | 1. Coarse warp is twice the diameter of the original yarn, 5~25cm long 2. Tight warp and suspended warp length 5~25 cm 3. Shrinkage length of 5 cm or less and width of 0.3 cm or less | 1. Coarse warp is twice the diameter of the original yarn, 5~15cm long 2. Tight warp length 5-15cm 3. The lifting length is 5-15cm, but it is not allowed to affect the flatness of cloth surface 4. It is not allowed to reduce the length by 5cm or less and the width by 0.3cm or less but affect the flatness of the cloth surface |

|

five | Coarse weft | 1-3 yarns twice the diameter of the original yarn | 1-3 yarns twice the diameter of the original yarn |

|

six | Slub yarn | 1~2 times thicker than the original yarn diameter, 2~4 pieces within 50cm of longitudinal length | 1~2 times thicker than the original yarn diameter, 2-3 pieces within 50cm in longitude |

|

seven | Weft contraction | The weft yarn is twisted and woven into the cloth or floated on the cloth in loops, 3 to 5 within 50cm of longitudinal length | Looping and weft shrinkage are not allowed |

|

eight | Skip yarn | Skip 0.2~0.3 cm for single yarn, 4~6 in 50 cm longitudinal length | Skip 0.2~0.3 cm for single yarn, 4~6 within 50cm of longitudinal length | 2~3 pieces of double layer cloth skip yarn, skip yarn is not allowed |

nine | Plaque | It does not affect the cloth surface, The longest length along longitude or latitude is 1-5cm | It does not affect the permission of flat cloth surface and disordered organization, It is not allowed to affect the smoothness and disorder of cloth surface |

|

ten | Colored yarn Dirty yarn Oiled yarn | The maximum length along the longitudinal or latitudinal direction is 5~25 cm | Oiled yarn is not allowed, colored yarn and dirty yarn are allowed |

|

eleven | Defective edge | The edge of the cloth is uneven, and every 1m along the warp direction, Dirty edges below 0.2 cm deep into the cloth edge are not counted | The edge of the cloth is uneven, and every 1m along the warp direction, Dirty edges below 0.2 cm deep into the cloth edge are not counted |

|

twelve | Oil stain Stain spot Stain Macular ulceration | The maximum length of the unwashed oil stain along the longitudinal or latitudinal direction is 0.2~2cm. The degree of stain, stain and shift stain is based on GB 250-94 Color change is compared with gray sample card, The maximum length along the longitudinal or latitudinal direction of the lower level 2~3 is 2~5cm | Oil shift and stain are not allowed | Any red spots caused by red flies are not counted as spots, Slight white spots caused by washing shall not be regarded as defects |

Continued Table 2

S/N | Defect name | Scope of defect detection | remarks |

Aviation and others | rubber |

thirteen | Rust | Dot burst | Rust stain caused by metal 0.1~0.2 cm | Rust caused by metal 0.1-0.2 cm | Three to five defects within 10 cm ² below 0.1 cm shall be weighed as one defect, Not allowed if there are more than 5, and not allowed if there are large areas of scattered |

fourteen | Broken edge | 0.3 cm or less deep into the selvage (2 yarns broken by the edge are not counted), the length is not more than 12 cm | 0.3 cm or less deep into the selvage (2 yarns broken by the edge are not counted), the length is not more than 12 cm |

|

fifteen | Disjunction | 0.5cm~1cm deep into the cloth edge, 3-5 pieces in each piece | 0.5cm~1cm deep into the cloth edge, 3-5 pieces in each piece |

|

sixteen | Bar transverse | Rosette | The color shall be compared with the gray sample card according to GB 250-94, Stripes and rungs below Grade 3 are 0.2cm wide and 20-50cm long |

|

|

seventeen | Deep and shallow edges | 3~5cm deep into the cloth, and the length along the edge shall not exceed 1m |

|

|

eighteen | chromatic aberration | Color difference of front, rear, left and right shall be changed according to GB 250-94 It is qualified if the gray sample card is not lower than Grade 3 | Color difference of front, rear, left and right shall be changed according to GB 250-94 It is qualified if the gray sample card is not lower than Grade 3 |

|

nineteen | Crinkle | Wrinkled cloth surface more than 1cm | Wrinkling is not allowed |

|

twenty | Latitudinal declination | The weft yarn is qualified if it is not more than 7% skewed in straight line or arc, 102, 105, 109, 110, 111 latitudinal inclination shall not exceed 5%, 119 latitudinal inclination not more than 6% | The weft yarn is qualified if it is not more than 7% skewed in straight line or arc, 102, 105, 109, 110, 111 latitudinal inclination shall not exceed 5%, 119 latitudinal inclination not more than 6% |

|

Table 3 Agreed piece length and allowable number of defects

Item No | Product Name | Specified piece length and Allowable tolerance m | Minimum segment length and false open

Minimum distance between shears m | Shortage of specified length

% of allowable quantity in meters | Allowable number of defects | Allowable number of false shearing |

one hundred and one | Natural color plain cloth, dyed plain cloth | 40-5 | four | three | seven | two |

one hundred and two | Plain cloth | 70-10 | nine | three | ten | three |

one hundred and three | Natural color fine plain cloth, flame retardant fine plain cloth | 40-5 | nine | three | seven | two |

one hundred and five | Plain cloth | 40-5 | nine | three | seven | two |

one hundred and seven | Plain cloth | 40-5 | ten | three | seven | two |

one hundred and nine | Natural color fine plain cloth, dyed fine plain cloth | 70-10 | nine | three | ten | three |

one hundred and ten | Anticorrosive fine plain cloth | 40-5 | seven | three | seven | two |

one hundred and eleven | Plain cloth with natural color lines | 40-5 | four | three | seven | two |

one hundred and twelve | Plain cloth with natural color thread and dyed thread | 40-5 | four | three | seven | two |

one hundred and thirteen | Dyed plain cloth | 70-10 | four | three | ten | three |

one hundred and fourteen | Silk light plain cloth | 40-5 | four | three | seven | two |

one hundred and fifteen | Plain cloth with natural color lines | 40-5 | seven | three | seven | two |

one hundred and sixteen | Silk light plain cloth, flame retardant line plain cloth | 40-5 | four | three | seven | five |

one hundred and seventeen | Dyed double-layer cloth, flame retardant double-layer cloth | 40-5 | three | three | seven | five |

one hundred and nineteen | Plain cloth | 70-10 | nine | three | eighteen | five |

Note: When 1 piece length is less than or exceeds the specified piece length, the number of defects allowed and the number of false shears allowed shall be converted in proportion.

2 The minimum length of rubber cloth shall be doubled according to Table 2. |

3.4.4 Dense path - the most obvious part shall prevail, and the number within 1 cm shall be measured and compared with the number converted to 1 cm by the tolerance on density.

3.4.5 Dilute weft - take the most obvious place as the standard, measure the number of pieces within 1 cm, and compare it with the number of pieces converted into 1 cm under the density tolerance.

3.4.6 Stain spot refers to the deep spot on dyed cloth caused by poor dye dissolution or the stain caused by gray cloth trimming and washing.

Stain - refers to the dirty spots on the surface of cloth during transportation, storage or processing, which can be removed by washing It belongs to such defects, such as mud, dust, reagent foot dirt, and stains caused by uncleanness of the machine body during finishing.

Oil stain refers to the oil stain on the other side of the cloth caused during weaving and processing.

Spots refers to the scouring spots, water spots, water stains and marks caused by various washing defects during processing.

3.4.7 Flaw removal refers to the partial small width of the cloth caused by the cloth rhenium slipping during stenting in printing and dyeing process.

3.4.8 Stripe - refers to the strip defects with dark and light colors or different shades when the cloth surface extends along the warp or weft, such as full-length dyeing stripe, scouring crepe stripe or rain stripe.

Rungs - long defects extending along the weft direction on the cloth surface, such as dyeing stalls caused by stop stops, joint prints or thin weft, and dense paths (not reaching the starting point of defects) of dyed cloth.

3.4.9 Wrinkle refers to the dead crease caused by calendering, and the impact dead crease caused by cloth running also belongs to this category.

3.4.10 Dark and shallow edge refers to the dark and shallow edge caused by uneven dyeing. When evaluating the deep and shallow edges, the edge tissue is folded 3 cm away from the cloth edge, and then compared with the normal color in the cloth.

3.4.11 Color difference refers to the color and light difference on the cloth surface or the defect with dark or light color. The color difference between the front and back refers to the color difference between the two ends of the cloth; Left and right color difference refers to the color difference on both sides of the cloth; Color difference between pieces refers to the color difference between any two pieces of cloth produced or delivered in the same batch.

4 Appearance defect inspection

Appearance defect inspection shall be carried out according to the provisions of GB/T 411, and the following supplementary provisions shall be made according to the use requirements of special industrial cotton cloth.

4.1 Piece by piece inspection.

4.2112, 114, 115, 116 and other four varieties shall be checked on both sides.

5 Test method

The physical and mechanical performance test shall be carried out according to the provisions of FZ 65001. The chemical property test shall be carried out according to FZ 65004.

The color fastness test shall be carried out according to GB 3920 Textiles Color Fastness to Rubbing, GB 3921 Textiles Color Fastness to Washing and GB 5714 Textiles Color Fastness to Sea Water.

6 Inspection rules

The inspection rules shall be in accordance with FZ65008.

7 Mark and package

Marking and packaging shall be in accordance with FZ 65006.