1 Scope

This standard specifies the test methods for physical and mechanical properties of special industrial ply yarn (including ply yarn of cotton fiber, silk fiber, hemp fiber and chemical fiber).

This standard is applicable to the test of general special industrial strand. Special industrial strand with special requirements, if any, shall be specified in the product standard or otherwise agreed by both parties.

2 Reference standards

The following standards contain provisions that, through reference in this standard, constitute provisions of this standard. When the standard is published, the versions shown are valid. All standards will be revised. All parties using this standard should explore the possibility of using new versions of the following standards.

GB 2543-81 Determination of Yarn Twist GB 8170-87 Rules for Rounding off Numerical Values

3 Sampling

3.1 Sampling proportion

For strand test, samples shall be taken from products of the same number, processing category and continuous production; One sample shall be taken for every 500 kg of cotton thread and raw silk thread, and one sample shall be taken for every 100 kg of silk thread and synthetic fiber strand produced by one barrel (or one slot, one box) during processing.

3.2 Sample quantity

Each test sample shall be taken according to the quantity given in Table 1.

Table 1 Sample Quantity

Finished product shape | For physical and mechanical property test | For moisture regain test |

Small ball of thread Large threadball Strand | 10 10 5 twisted | About 200g |

Note: When the delivery quantity is less than 50kg, the sample for the moisture regain test of the package can be reduced to about 50g |

4 Test conditions

4.1 The standard atmospheric conditions of the laboratory are temperature 20 ± 3 ℃ and relative humidity 65 ± 5%.

4.2 Under the above specified temperature and relative humidity conditions, the cotton thread shall be placed loosely for 24h, and the silkworm silk thread and synthetic fiber thread shall be placed loosely for 4h, and the test shall be conducted under this condition.

4.3 Twist test and moisture regain test are not subject to the above conditions.

5 Test items

5.1 Weight

5.1.1 Test instruments

5.1.1.1 Yarn length measuring machine with standard loop length of 1m.

5.1.1.2 0.01g sensitive industrial balance.

5.1.2 Test preparation

5.1.2.1 The perimeter deviation of the yarn length measuring machine is ± 1 mm.

5.1.2.2 The yarn frame rotation speed is 90 ± 5r/min.

5.1.2.3 Stranded wire must pass 21~28g tension spring or other corresponding tension devices when winding.

5.1.2.4 Each sample shall be tested 20 times, and the length of each test shall be 20m.

5.1.3 Test operation

5.1.3.1 Shake 20 strands of each sample according to 5.1.2.

5.1.3.2 Weight measurement: Weigh 20 strands of strand wire one by one, accurate to 0.01g.

5.1.3.3 Measurement of drying weight: weigh the 20 strands of strands shaken to an accuracy of 0.01 g (to calculate the weight or unevenness of the number of strands), bake the 20 strands of strands to dryness according to the moisture regain test method in 5.4 of this standard, and then weigh the total dry weight of the 20 strands of strands.

5.1.4 Weight representation

5.1.4.1 The weight of strands is expressed as 100 m weight or 100 m dry weight.

5.1.4.2 The weight is calculated to 0.01 g and rounded to 0.1 g.

5.2 Breaking strength and elongation

5.2.1 Test instruments

Single wire strength testing machine with elongation measuring device.

5.2.2 Test method

5.2.2.1. The application range of the strength tester shall be 20~80% of the full scale.

5.2.2.2 Both the strong pointer and the extension pointer should be at the "0" point.

5.2.2.3 Descending speed when the lower clamp is not under load:

a) Cotton thread 500 mm/min;

b) Silkworm silk thread 250 mm/min;

c) Synthetic fiber line 250 mm/min;

d) Hemp thread 500 mm/min.

5.2.2.4 The distance between the upper and lower clamps of the strength tester and the test times are given in Table 2.

5.2.2.5 The pretension weights of various strands are given in Table 3, 4 and 5.

5.2.3 Test operation

At the beginning of the test, first put down the clamp, fix the upper clamp, insert one end of the strand (the strand shall be led out from the longitudinal direction of the coil) into the upper clamp, tighten the upper clamp, and then insert the other end of the strand into the lower clamp, and add the specified pre tension weight to make the strand vertical due to a slight drop of gravity, then loosen the clamp, tighten the lower clamp, and remove the weight for the test, Until the strand breaks, read its strength. If it is necessary to know the elongation, the elongation shall be recorded at the same time. The breaking strength and elongation shall be read to the minimum scale of the dial and scale.

Table 2 Clamp distance and test times of strength tester

Type of strand | Distance between upper and lower clamps mm | Number of tests |

Cotton thread | five hundred | fifty |

Silkworm silk thread | two hundred | twenty |

Synthetic fiber thread | two hundred | twenty |

Twine | five hundred | fifty |

Table 3 Cotton Thread Pre tension

100 meter standard weight g | 5 and below | Above 5 to 10 | Above 10 to 15 | Above 15 to 22 | Above 22 to 30 | Above 30~40 |

Pre tension weight g | ten | twenty | thirty | fifty | seventy | one hundred |

Table 4 Pretension of Silk and Synthetic Fiber Lines

100 meter standard weight g | 6 and below | Above 6 to 10 | Above 10 to 15 | Above 15 to 25 | Above 25 to 35 | Above 35 |

Pre tension weight g | ten | twenty | forty | seventy | one hundred | one hundred and fifty |

Table 5 Hemp Pretensioning

100 meter standard weight | 7 and below | Above 7 to 12 | Above 12 to 17 | Above 17 to 25 | Above 25 to 35 | Above 35 to 45 | Above 45 to 55 |

Pre tension weight g | five | ten | fifteen | twenty | thirty | forty | fifty |

100 meter standard weight g | Above 55 to 65 | Above 65 to 75 | Above 75 to 85 | Above 85 to 95 | Above 95 to 110 | Above 110 to 135 | Above 135 |

Pre tension weight g | sixty | seventy | eighty | ninety | one hundred | one hundred and twenty | one hundred and fifty |

5.2.4 Expression method of breaking strength

The breaking strength of strand refers to the number of loads when a specified length of strand breaks, and its unit is N. The test results are expressed in arithmetic mean

Count to 0.01 N and round to 0 1N。

5.2.5 Expression method of elongation

Elongation refers to the elongation of the tested strand when it is broken when measuring the strength of the strand.

Where: E -- Elongation,%;

L ₁ - length of strand when it is broken, cm;

O -- original length of strand, cm。

The elongation test results are expressed in arithmetic mean, which is calculated to 0.01% and rounded to 0.1%.

5.2.6 Precautions

5.2.6.1 If the strand slips or breaks in the clamp (within 10 mm from the clamp edge) during the test, another strand shall be retested. If the strength exceeds the standard, there is no need to retry.

5.2.6.2 In case of any abnormal phenomenon (including test readings and machinery, etc.) during the test, the test shall be stopped immediately to check and analyze the cause.

5.2.6.3 During operation, prevent the strand from being tilted in the upper and lower jaws.

5.2.6.4 During the test, the "0" point of the strong pointer and the extension pointer shall be frequently observed. If there is any change, it shall be adjusted in time.

5.3 Twist test method

Twist test shall be carried out according to GB 2543.

5.4 Moisture regain test method

5.4.1 Test instrument

5.4.1.1 Oven with 0.01 g sensitive industrial balance.

5.4.1.2 0.01g sensitive industrial balance.

5.4.2 Test operation

5.4.2.1 Take about 200g of sample, weigh it immediately, and weigh it accurately to 0.01g.

5.4.2.2 Bake the sample in an oven at 105~110 ℃ to a constant weight (i.e. dry weight). Constant weight means that the difference between the two weights every 10 min does not exceed 0.05% of the original weight, and the last weight shall prevail.

5.4.3 Calculation method

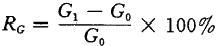

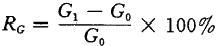

The moisture regain is calculated according to the following formula:

Where: Rc -- actual moisture regain,%;

G ₁ - weight of sample before baking, g;

G ₀ - constant weight of sample after baking, g。

The moisture regain is calculated accurately to 0.001% and rounded to 0.01%.

5.4.4 Precautions

5.4.4.1 The dry weight of the sample shall be weighed in the oven.

5.4.4.2 The weight of the drying basket of the oven shall be corrected at 105~110 ℃, which shall prevail.

5.4.4.3 When weighing the dry weight, the weighing shall be started 3 min after the button is turned off (turned on after weighing) and finished within 10 min.

5.4.4.4 If the total weight of the sample exceeds the balance, it shall be weighed separately, and the moisture regain shall be calculated based on the total weight.

5.5 Synthesis and retest of test results

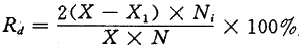

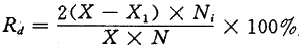

5.5.1 The unevenness of various tests shall be calculated according to the Chamel formula:

Where: R - unevenness,%;

X - arithmetic mean of all test values;

X ₁ - arithmetic mean of the following test values;

N ₁ - the average number of the following test values;

N -- Total number of tests.

Note: If the test value is equal to the average (X), the test value below the average will not be calculated.

5.5.2 When calculating the average, the rounding method shall follow the provisions of GB 8170.

5.5.3 If any index of the sampled test result does not meet the standard, two samples shall be taken for the retest of the item, and the retest result is qualified when both samples meet the standard.